Function of air preheater:

1. Improve and strengthen combustion: The air after the waste heat exchanger enters the furnace, accelerating the drying, ignition and combustion process of fuel, ensuring stable combustion in the boiler, and improving the combustion efficiency.

2. Enhanced heat transfer: as the combustion in the furnace has been improved and strengthened, and the temperature of hot air entering the furnace has been increased, the average temperature level in the furnace has also been increased, which can strengthen the radiation heat transfer in the furnace.

3. Reduce the loss in the furnace, reduce the exhaust gas temperature, and improve the thermal efficiency of the boiler. As the combustion in the furnace is stable and the radiation heat exchange is strengthened, the chemical incomplete combustion loss can be reduced; On the other hand, the air preheater uses the waste heat of flue gas to further reduce the loss of flue gas, thus improving the thermal efficiency of the boiler. According to experience, when the air in the preheater rises by 1.5 ℃, the exhaust gas temperature can be reduced by 1 ℃. After installing the air preheater in the boiler flue, if the air waste heat can be 150-160 ℃, the exhaust gas temperature can be reduced by 110-120 ℃, and the boiler thermal efficiency can be increased by 7% - 7.5%. Fuel can be saved by 11% - 12%.

4. Hot air can be used as fuel desiccant: for layer combustion furnace, hot air can be used as fuel with high moisture and ash content. For power station boiler, hot air is an important desiccant and pulverized coal conveying medium in the pulverizing system.

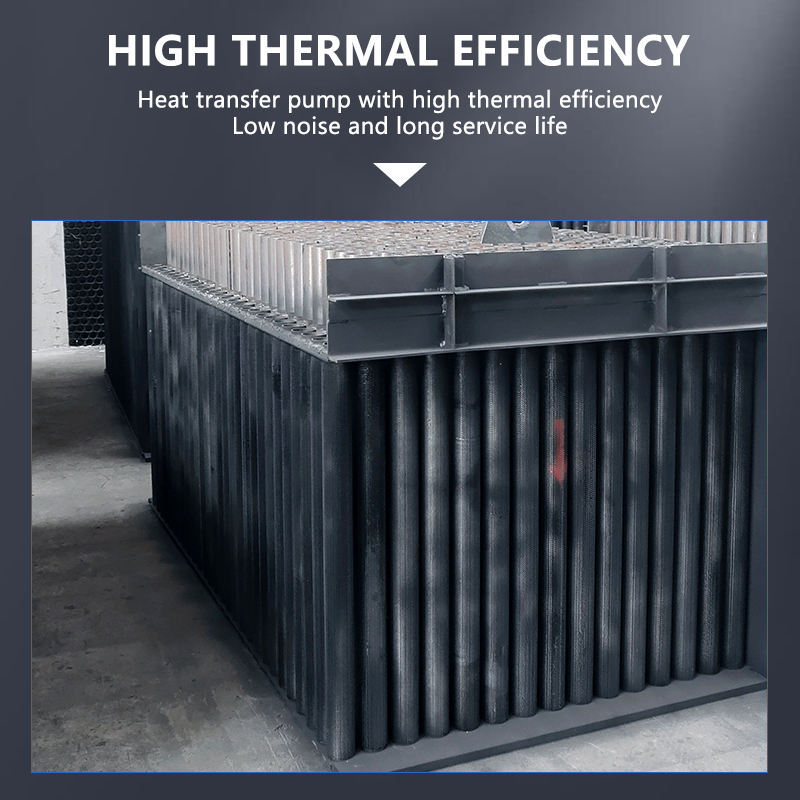

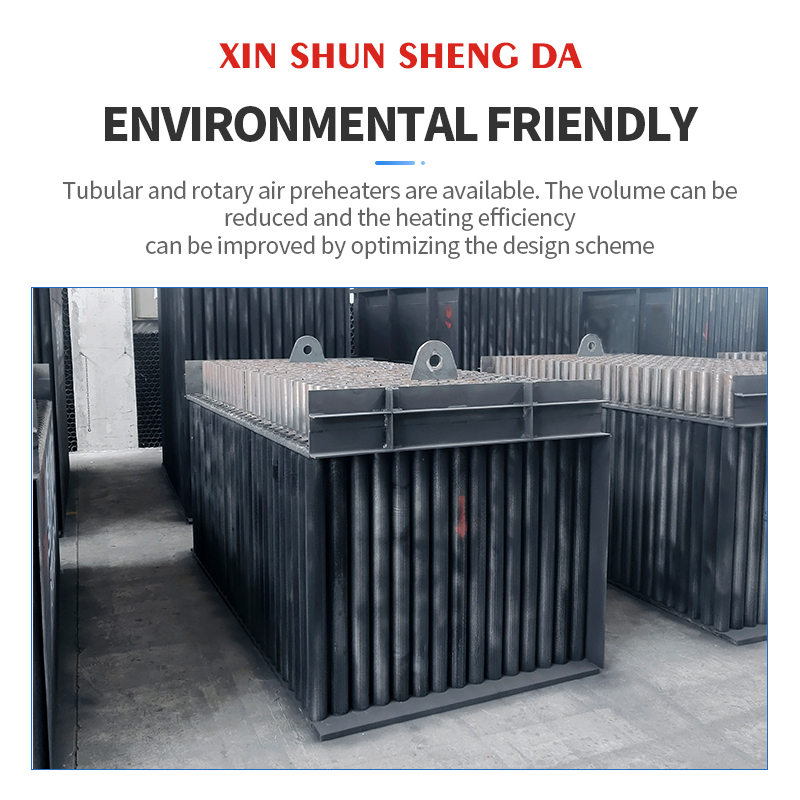

Air preheater, also called air preheater for short, is a kind of preheating equipment to improve the heat exchange performance of boiler and reduce heat loss. The function of the air preheater is to transfer the heat carried by the flue gas discharged from the tail flue of the boiler to the air before entering the boiler through the radiator to preheat the air to a certain temperature.

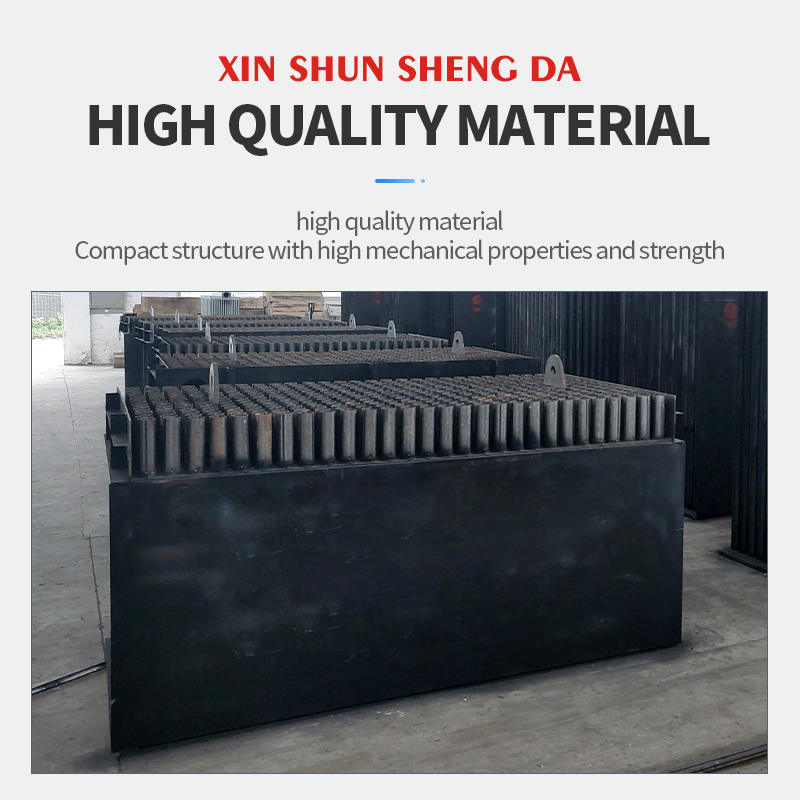

The three-dimensional fin is processed by cutting the inner and outer walls of the metal tube, which is not only a new processing technology, but also a technology to enhance heat transfer. The heat transfer effect of this type of heat exchange tube is 2.5-6 times higher than that of ordinary smooth tubes. Three dimensional finned tube is a new generation of non continuous enhanced heat transfer tube composed of fins. The fin erosion caused by three-dimensional fluid flow is better than that caused by two-dimensional fluid flow, and it has stronger anti fouling ability and heat transfer ability. Integrated processing, no contact thermal resistance; The tube wall temperature can be adjusted by adjusting the number, height and layout of fins, which is conducive to reducing the risk of low-temperature corrosion; The spacing of heat exchange tubes can be appropriately increased, which is conducive to ash removal and maintenance and tube replacement; The heat transfer inside and outside the tube is enhanced at the same time, which makes the heat exchanger more efficient and compact. It is an efficient heat transfer element with excellent heat transfer performance. In terms of processing technology, this technology breaks through the current international processing technology that can only process copper, aluminum and other soft metal materials, and expands the materials to steel, stainless steel, titanium and other ductile metals, so that heat exchangers in all industries can use this type of finned high efficiency heat exchanger.

The size can be customized according to customer needs, welcome to consult.

Chongqing Xinshun Shengda Technology Co., Ltd. was established on August 26, 2020, with its registered address at No. 5, Chuangxin Avenue, Changzhou Street, Rongchang District, Chongqing, and its legal representative is Xia Hao. The business scope includes the licensed project: construction engineering construction. General items: technical service, technical development, technical consultation, technical exchange, technology transfer and technology promotion; R&D of key technologies for waste heat power generation; Sales of gas and liquid separation and purification equipment; Energy conservation management services; Research and development of efficient energy-saving technologies in the power industry; Manufacturing of refrigeration and air conditioning equipment; Sales of refrigeration and air conditioning equipment.

An energy-saving and environment-friendly high-tech enterprise developed on the basis of Chongqing University 3D Energy Saving Technology Development Co., Ltd., which was established in 1991. Driven by new energy-saving technologies, the company tailors an optimization scheme for the comprehensive utilization of energy for enterprises and provides energy-saving and environment-friendly heat exchange products and technical services for enterprises.

Wang Lei

104555668@qq.com